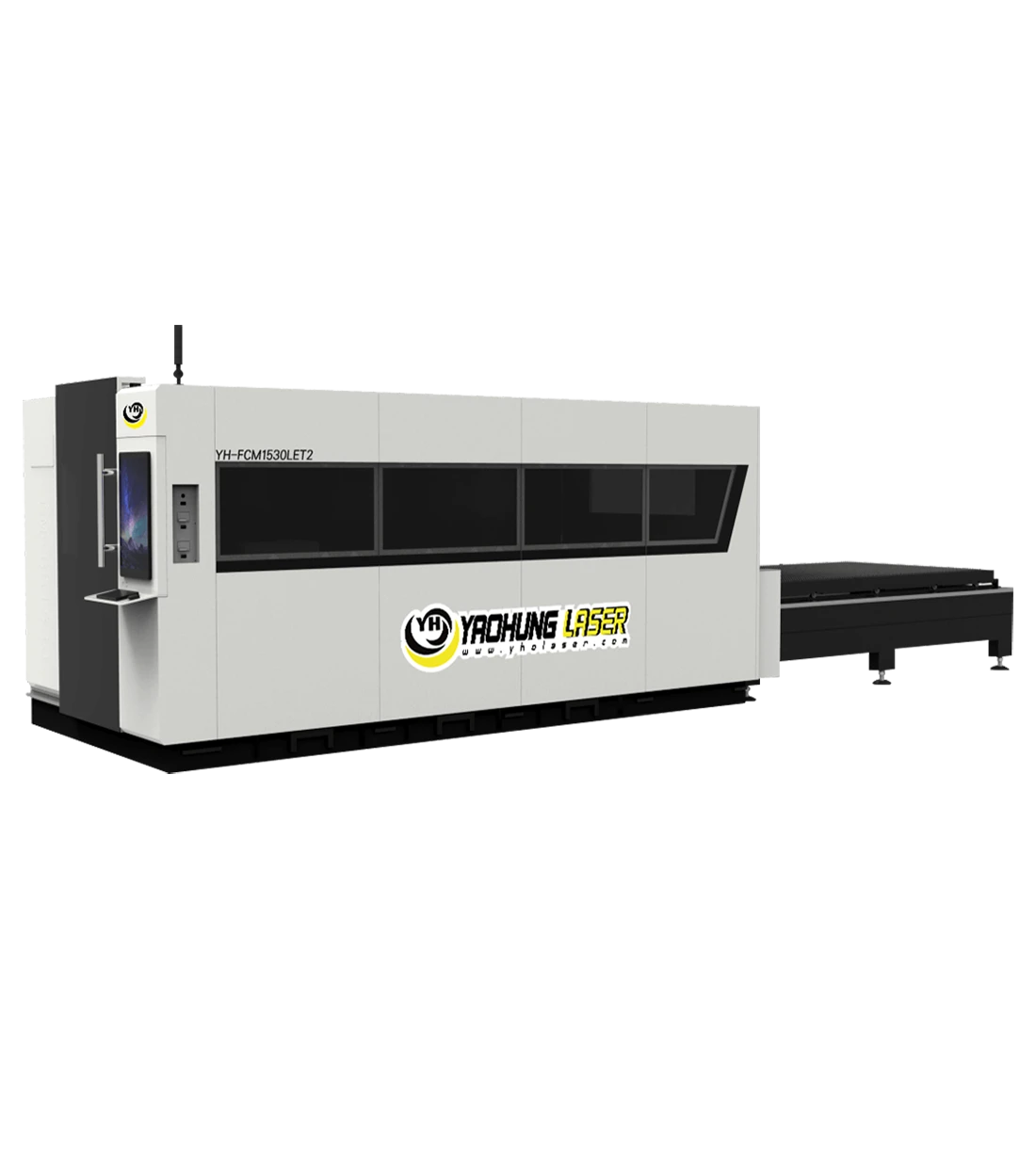

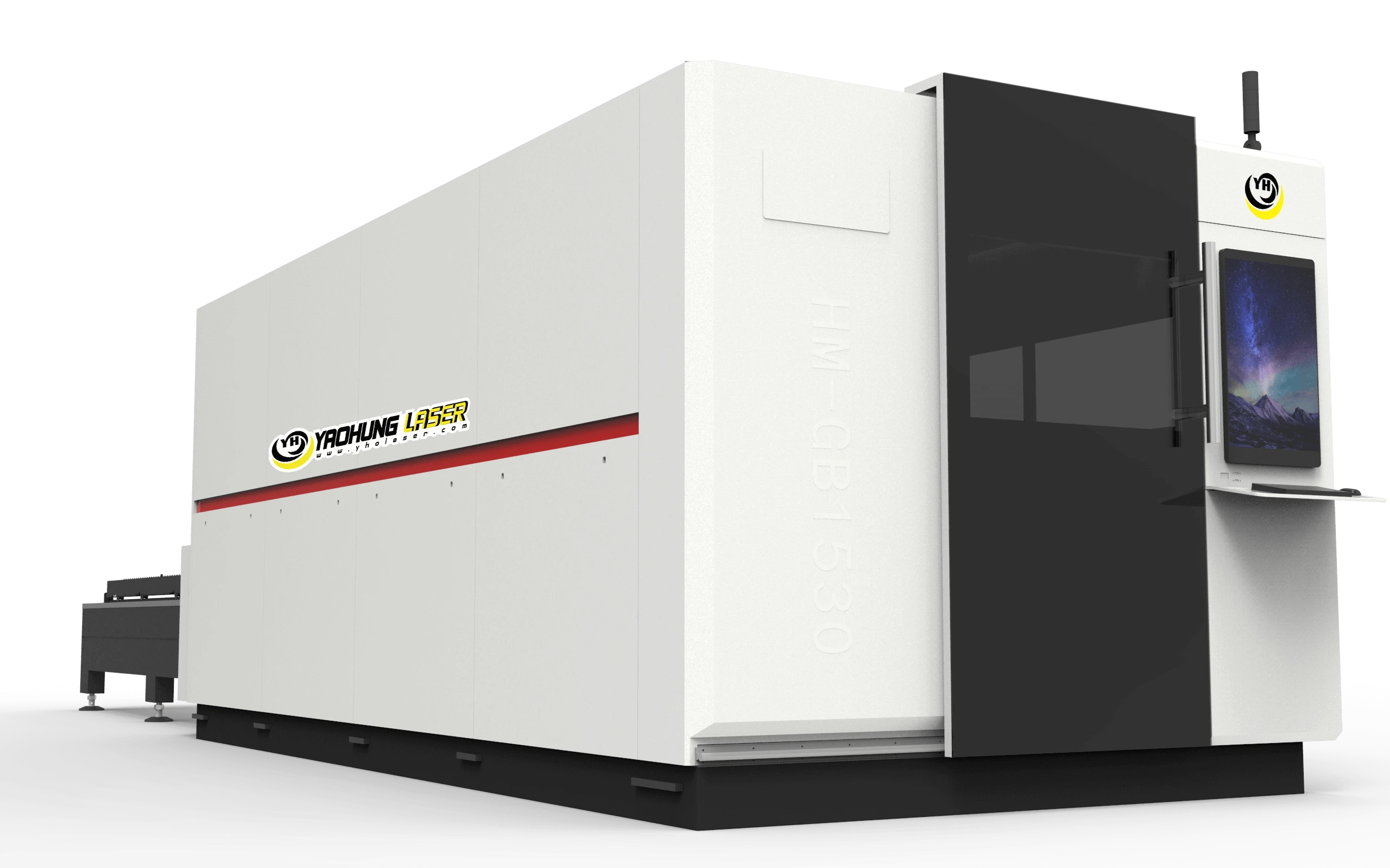

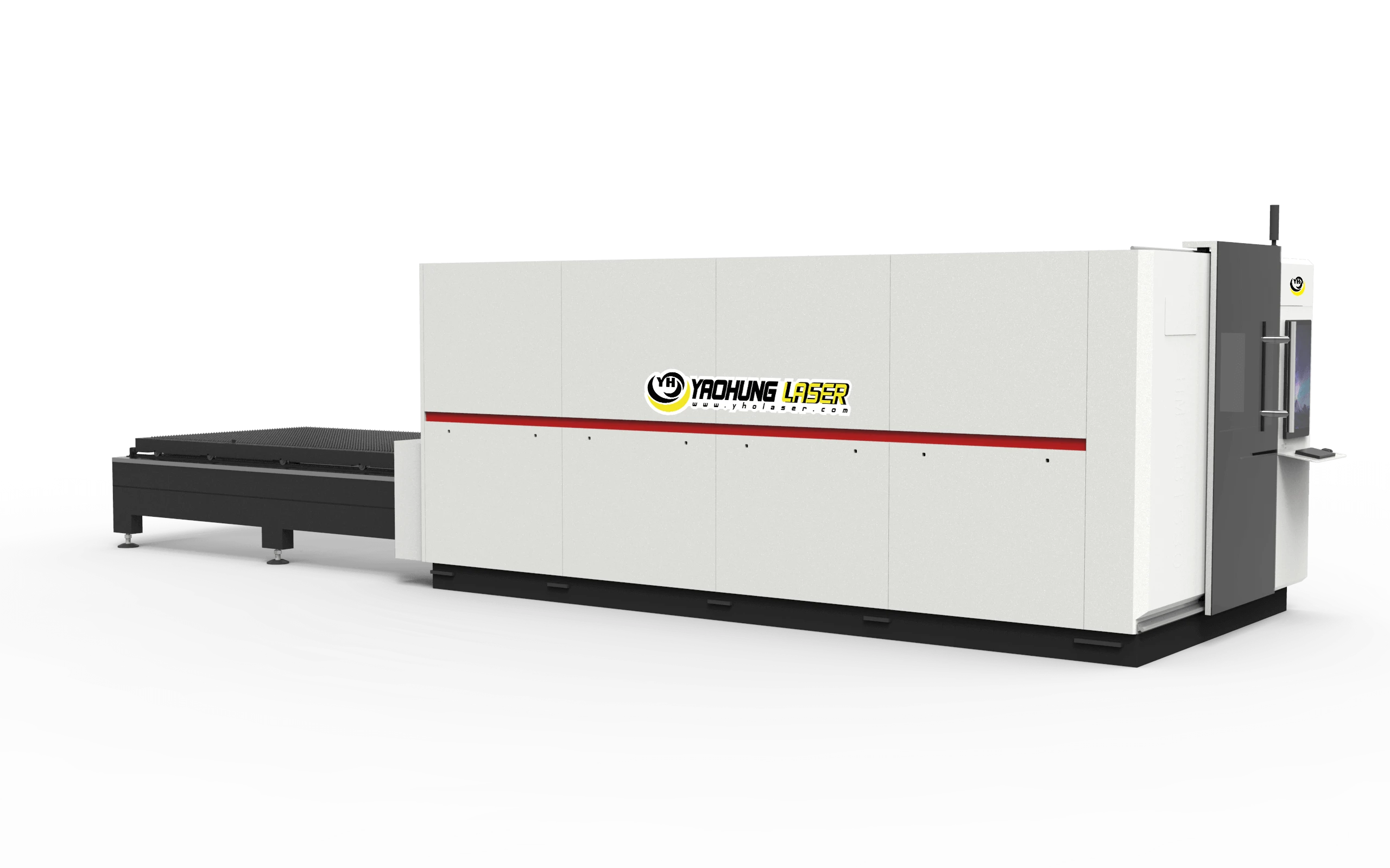

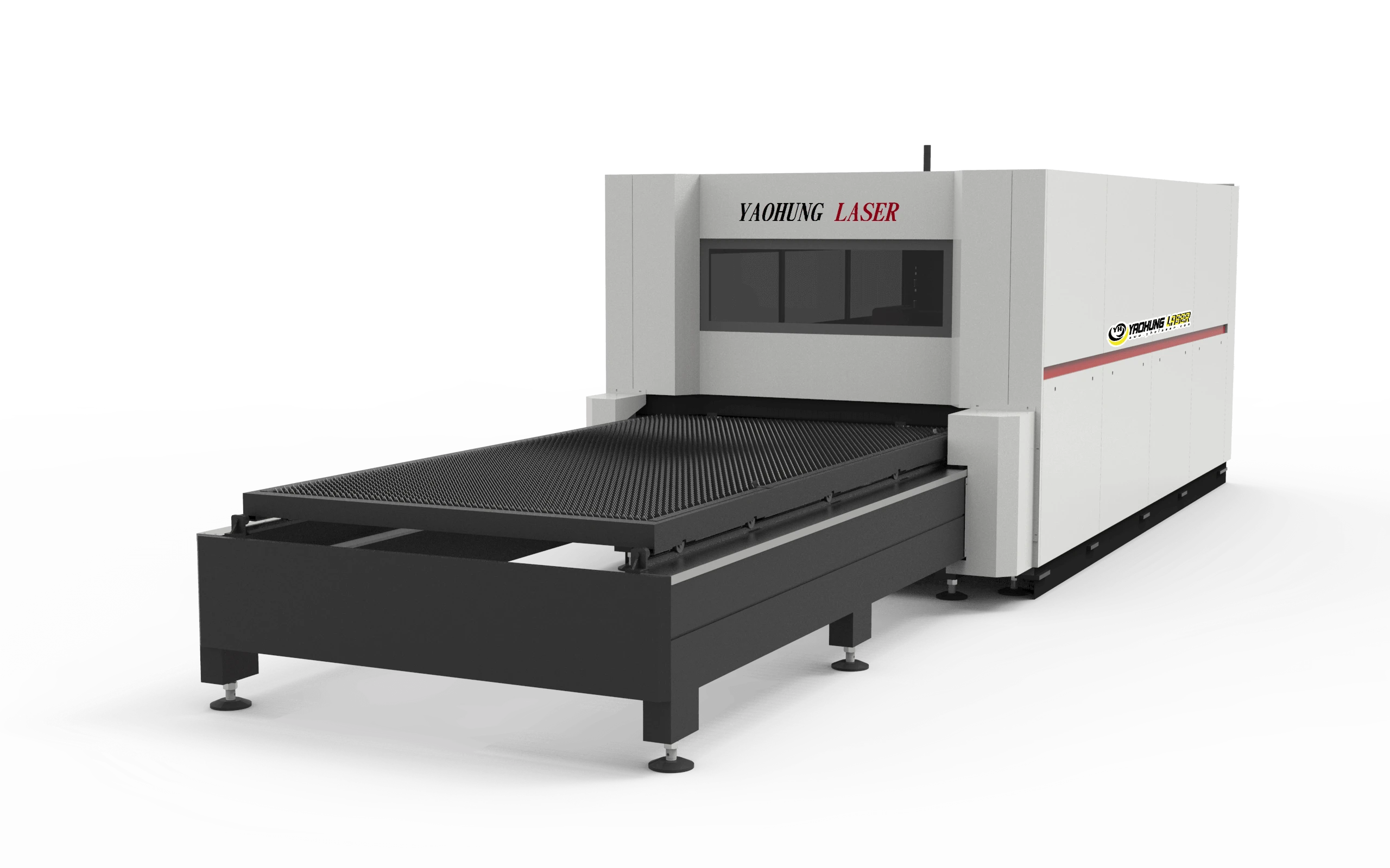

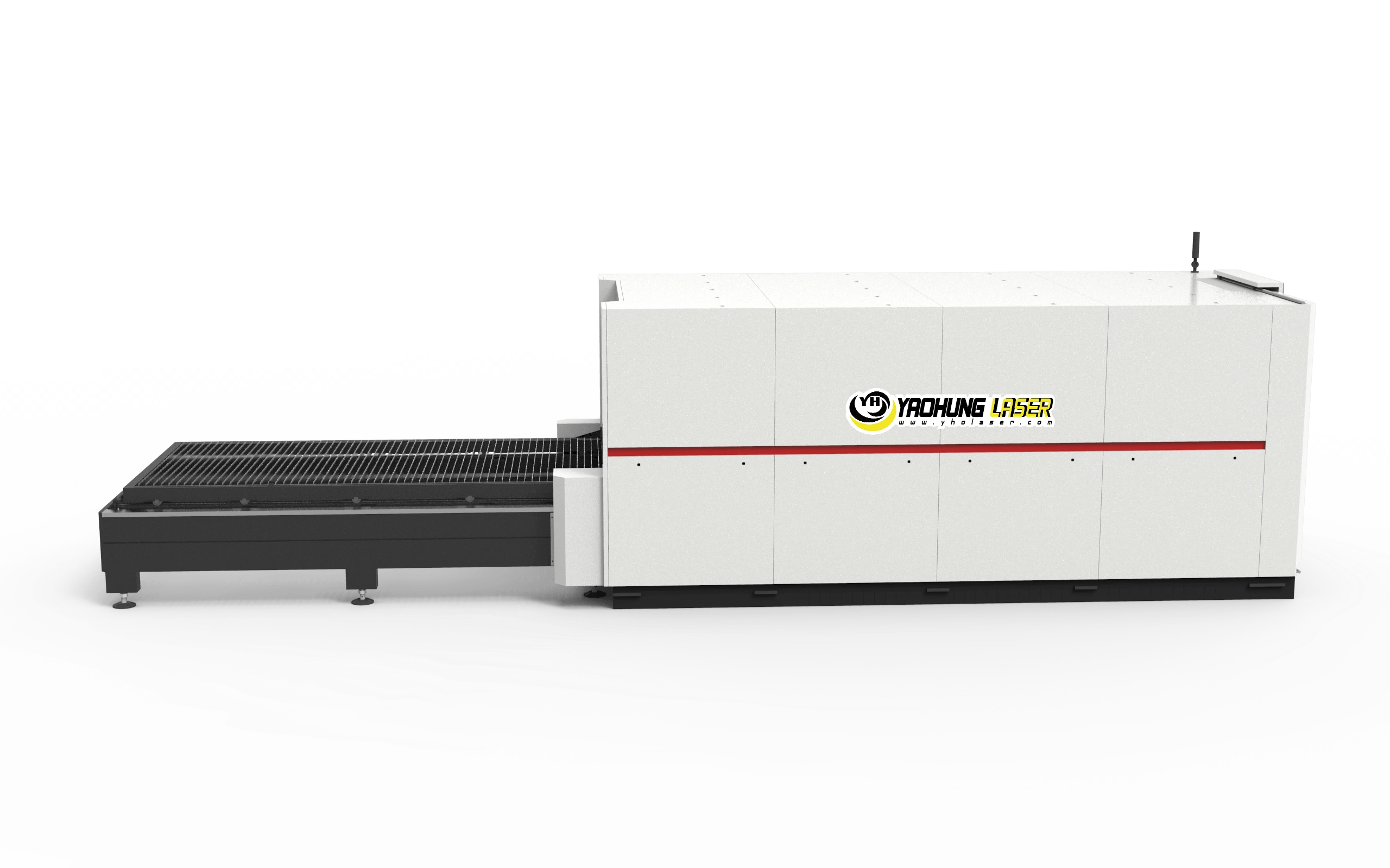

Large Sheet Metal Cutting Machine - Fully Enclosed Exchangeable Table

YH-30_LCSTT2_53FSOF / YH-60_LCSTT2_36FSOF

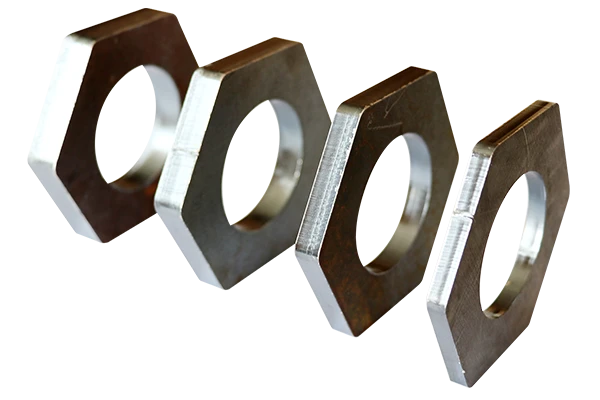

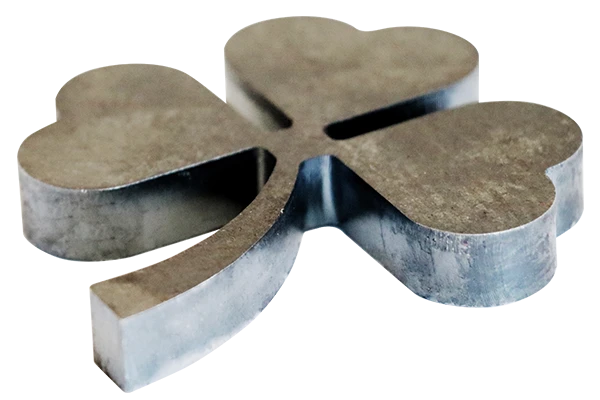

Applicable materials and industry applications

- Suitable for various metals and alloys.

- Widely used in sheet metal processing, mechanical equipment, electrical appliances, steel structures, chassis cabinets, elevator manufacturing, shipbuilding, advertising and other industries.

Optimize Your Workflow with Customized Laser Systems

From concept to configuration — We build it your way.

Explore Custom Solutions