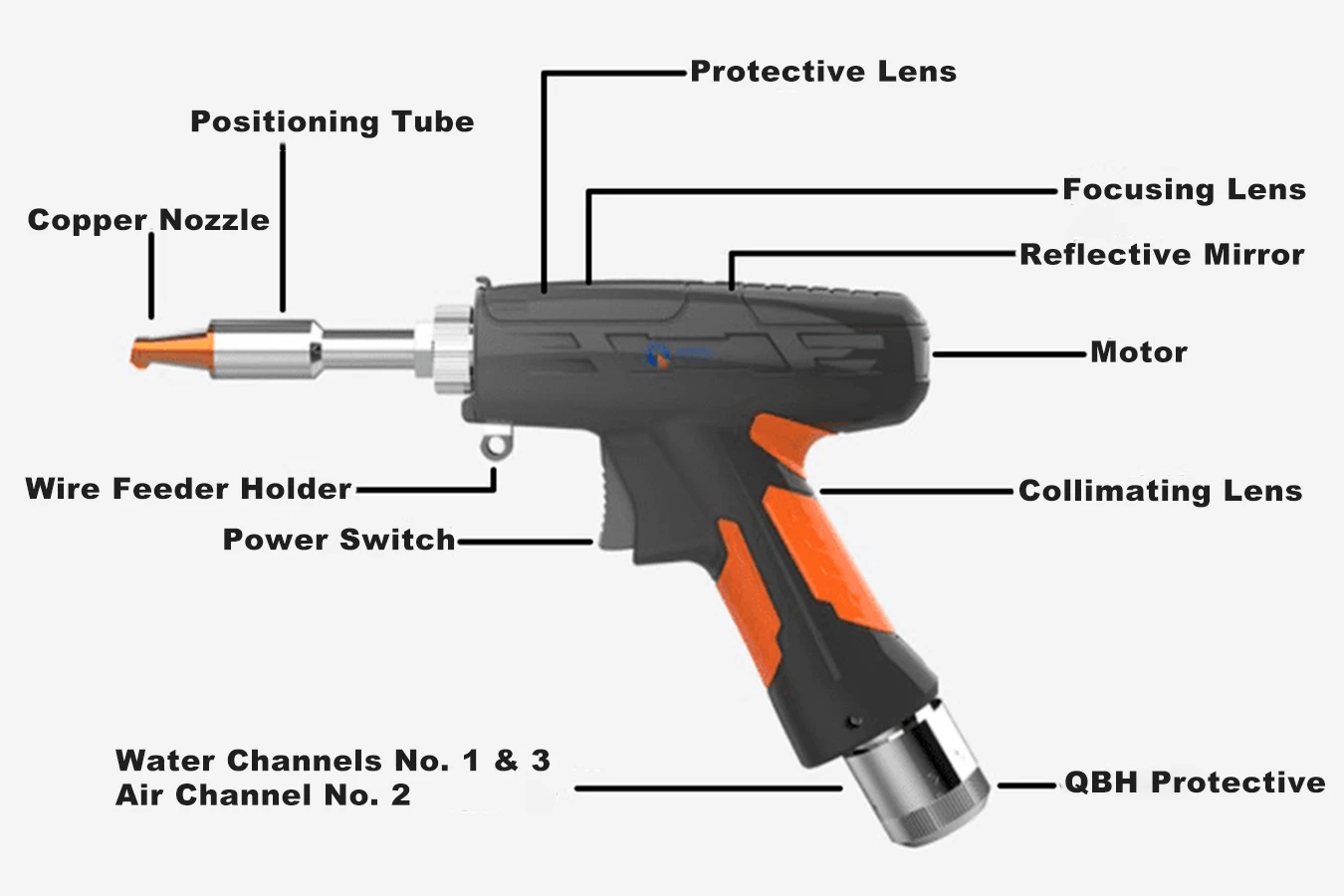

Dual wire feed handheld laser welding machine

YH-30_LWHD_OF

Dual Wire Feed

Deep Weld Stability

Weld & Cut

Multi-Material Use

Applications & Materials

- Copper, carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet and other metal and alloy materials.

- Welding of sheet metal industry, hardware cabinets, household appliances, advertising signs, molds, metal doors and windows, hardware crafts, auto parts, and many other industries and related products.

Frequently Asked Questions

Dual wire feed means feeding filler material from both sides simultaneously. It effectively compensates for wide gaps or misaligned joints that may cause porosity or shrinkage cracks.

Compared to single wire feed, which only fills from one side, dual wire feed creates a fuller molten pool and more stable weld seam. This is particularly suitable for aluminum, thick plates, and irregular joints. It also improves airtightness and weld strength consistency, reducing the need for rework and secondary grinding.

Compared to single wire feed, which only fills from one side, dual wire feed creates a fuller molten pool and more stable weld seam. This is particularly suitable for aluminum, thick plates, and irregular joints. It also improves airtightness and weld strength consistency, reducing the need for rework and secondary grinding.

Dual wire feed handheld laser welding is widely used in sheet metal cabinets, home appliance panels, aluminum cases, elevator doors, and tool cabinets where appearance and structural strength are critical.

It is also ideal for correcting assembly errors or edge misalignments, such as aluminum frames, panel edges, and enclosure reinforcements. In production lines handling medium-thickness plates where precise positioning is difficult, it provides a flexible compensation solution.

It is also ideal for correcting assembly errors or edge misalignments, such as aluminum frames, panel edges, and enclosure reinforcements. In production lines handling medium-thickness plates where precise positioning is difficult, it provides a flexible compensation solution.

Weld seams are generally smooth and even, so in most cases only minor finishing is needed before painting or assembly.

Since dual wire feed fills the entire joint area, the welds look natural with neat edges, significantly reducing re-welding or heavy grinding. For sheet metal factories, it shortens manual work time and improves product consistency.

If you deal with precision components (such as semiconductor packaging, medical devices, or sensor modules) or require automation line integration, we recommend our platform laser welding machine series, which supports multi-axis positioning and smart welding for stable, high-precision production.

Since dual wire feed fills the entire joint area, the welds look natural with neat edges, significantly reducing re-welding or heavy grinding. For sheet metal factories, it shortens manual work time and improves product consistency.

If you deal with precision components (such as semiconductor packaging, medical devices, or sensor modules) or require automation line integration, we recommend our platform laser welding machine series, which supports multi-axis positioning and smart welding for stable, high-precision production.

Related Product

Optimize Your Workflow with Customized Laser Systems

From concept to configuration — We build it your way.

Explore Custom Solutions