Cabinet-Type

YH-03_LCGCT_PE / YH-05_LCGCT_PE

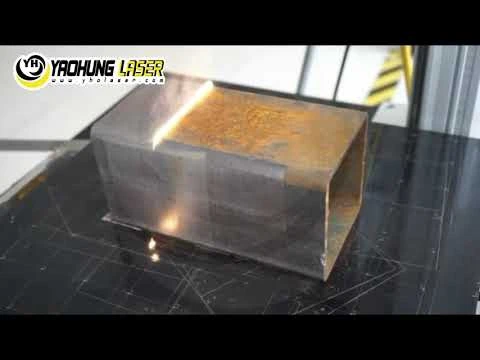

- Utility Cabinet-Type Laser Cleaning Machine is designed as a stationary workstation model, ideal for implementing automated cycle cleaning, heavy contamination pre-treatment, or environments requiring multi-machine coordination.

- Supports contamination removal on materials such as aluminum alloys, stainless steel, mold steel, galvanized steel, stone, and wood, including weld marks, coatings, rust, oil stains, and carbonized layers.

- Widely applied in mold rework stations, electronics manufacturing processes, and aerospace and automotive supply chain stations. Also suitable for integration with cleaning workstations, loading/unloading systems, and visual positioning setups.

FAQ

Cabinet Laser Cleaner supports process-based automated cleaning, equipped with parameter storage and fixed workstation control modules. It can be integrated with coating, welding, anodizing, and other processes, serving as a core cleaning station for automated production lines.

The Cabinet Laser Cleaner is equipped with a retractable touchscreen and a multilingual graphical interface, supporting 16 languages including Traditional Chinese, Japanese, and English.

It is designed for non-engineering operators, factory inspections, and OEM maintenance environments. Deployment is simple and error-free.

The Cabinet Laser Cleaner is particularly suitable for:

- Refurbishing old mold coatings and removing adhesive residues (die-casting molds, injection molds, etc.)

- Removing carbonized layers on electronic components and calibrating electrode precision

- Protective cleaning of high-end metalwork and cultural heritage artifacts

With a focal display module, dustproof cleaning head, and air-water separation design, it ensures stable laser output and consistent high precision.

Optimize Your Workflow with Customized Laser Systems

From concept to configuration — We build it your way.

Explore Custom Solutions