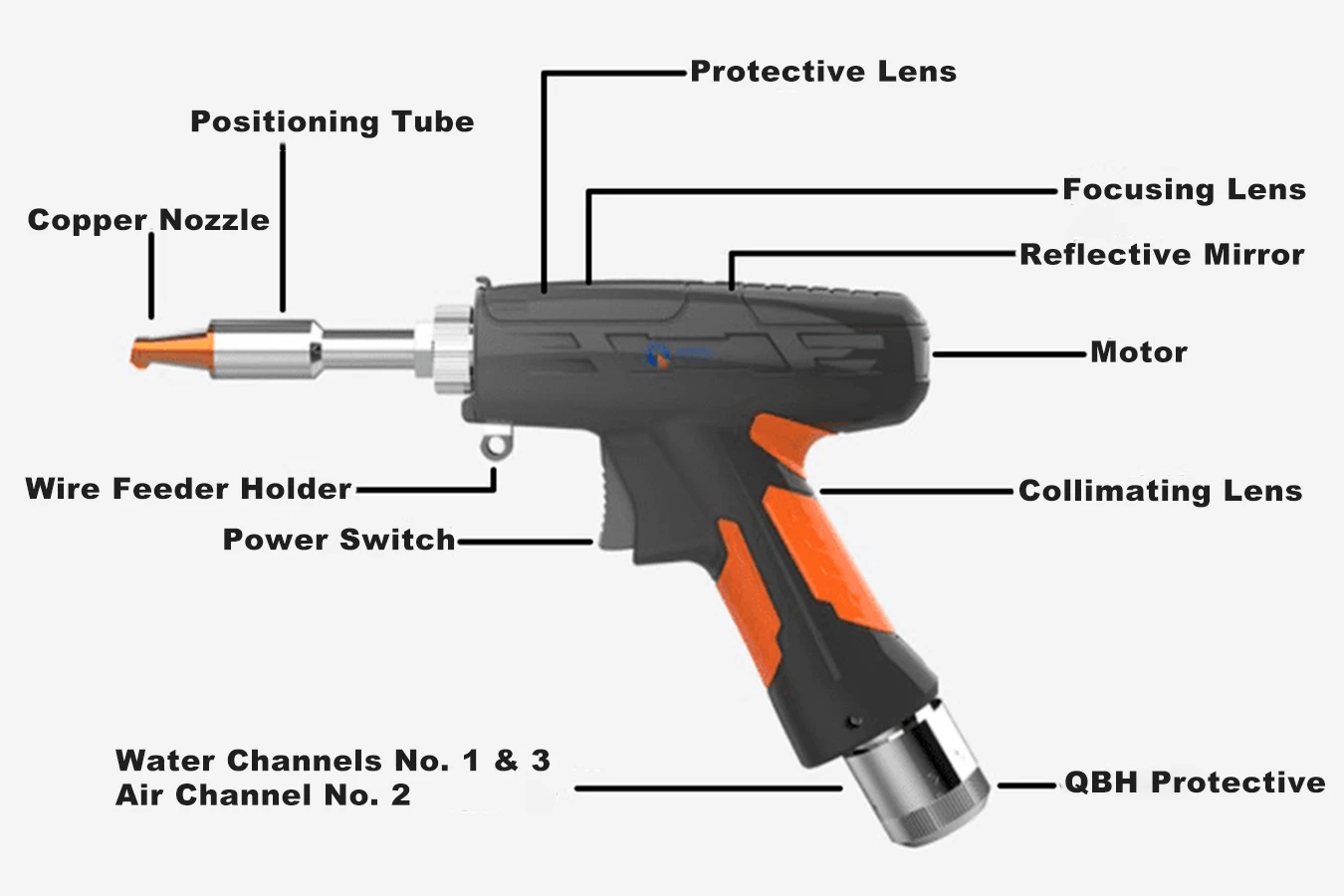

Handheld fiber optic continuous laser welding machine

YH-15_LWHD_OF / YH-20_LWHD_OF

Built-In Cooling System

Energy Efficient

Modular Design

Applications & Materials

- Various metals and alloys.

- Welding of kitchen stoves, kitchen hardware, sheet metal industry, advertising signs and other products.

Frequently Asked Questions (FAQ)

Especially suitable for 0.5 mm – 2.5 mm thin metal sheets such as stainless steel and aluminum alloys.

With high energy density and short heat input, laser welding minimizes thermal deformation and penetration risks. The weld seam is smooth with minimal discoloration, reducing post-processing. Ideal for sheet metal edging, kitchen equipment, and thin-shell structures.

With high energy density and short heat input, laser welding minimizes thermal deformation and penetration risks. The weld seam is smooth with minimal discoloration, reducing post-processing. Ideal for sheet metal edging, kitchen equipment, and thin-shell structures.

Yes. This equipment adopts an all-in-one design with integrated cooling and control modules, requiring no welding table or fixed platform. It is portable for on-site operations, commonly used in building structures, signage, and pipe repair.

With only a basic power supply and shielding gas, high-efficiency outdoor welding is possible.

With only a basic power supply and shielding gas, high-efficiency outdoor welding is possible.

No. The handheld welder is equipped with a touch control panel and preset parameter templates, allowing quick learning with minimal training.

Compared with TIG welding or arc welding, laser welding relies on system stability and optical precision, greatly lowering the skill barrier. For mass automation, we recommend the Platform-type Laser Welding Machine Series, which supports robotic arms and modular expansion.

Compared with TIG welding or arc welding, laser welding relies on system stability and optical precision, greatly lowering the skill barrier. For mass automation, we recommend the Platform-type Laser Welding Machine Series, which supports robotic arms and modular expansion.

Related Product

Optimize Your Workflow with Customized Laser Systems

From concept to configuration — We build it your way.

Explore Custom Solutions