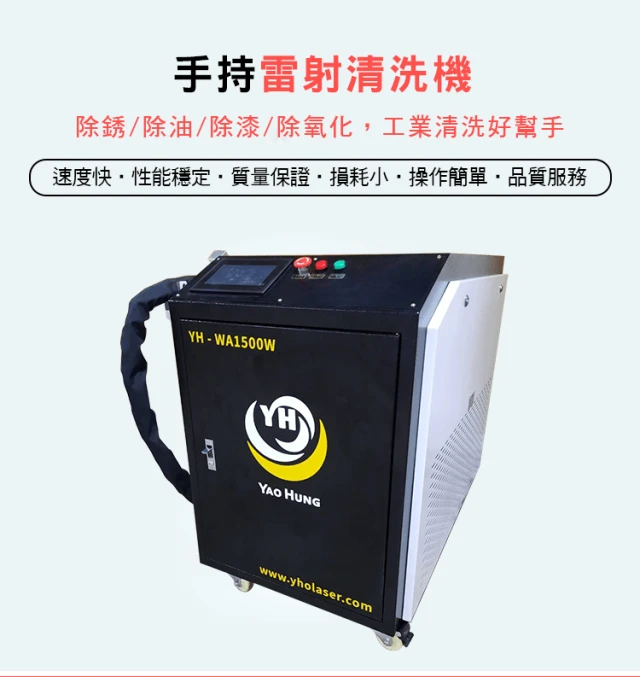

Handheld-Type

YH-15_LCGHD_OF / YH-20_LCGHD_OF / YH-30_LCGHD_OF

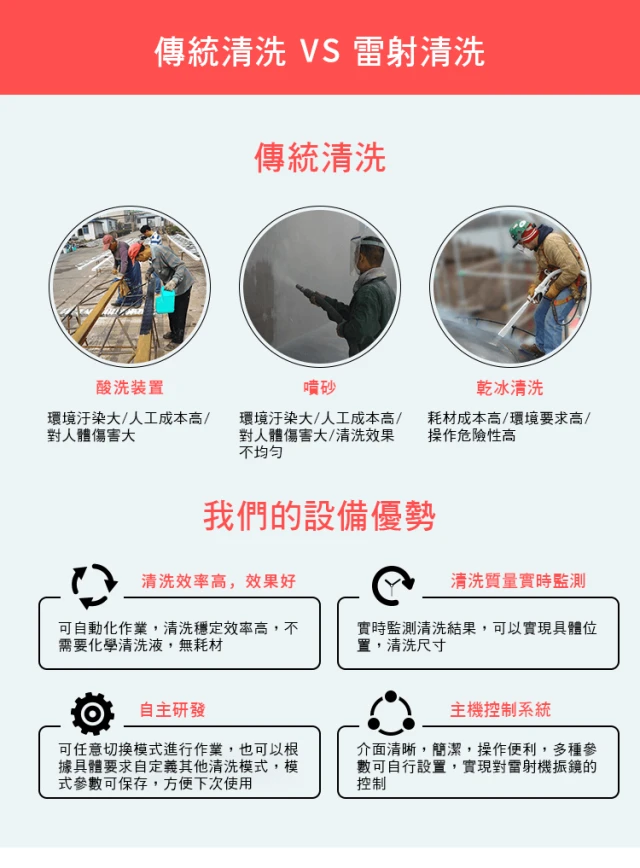

- Handheld Laser Cleaning Machine focuses on mobile deployment and rapid on-site treatment, ideal for heavy contamination, severe rust, or coating removal tasks.

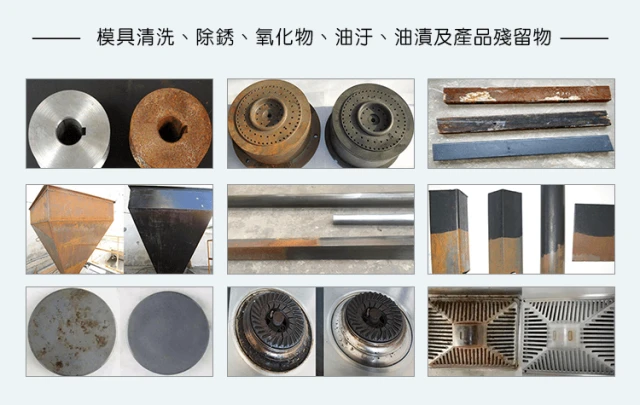

- Suitable for steel structures, carbon steel, stainless steel, iron parts, large panels, and complex curved surfaces. Common targets include weld slag, surface rust, paint layers, and oxide scale.

- Widely used in building steel frameworks, ship maintenance, pipeline installation, mold refurbishment, and industrial equipment servicing. Also supports cycle-based large-area contamination removal.

FAQ

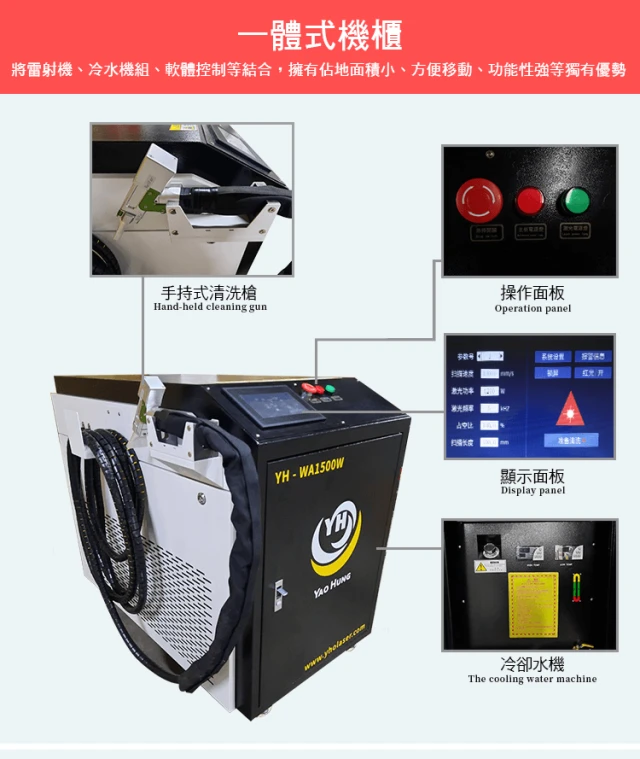

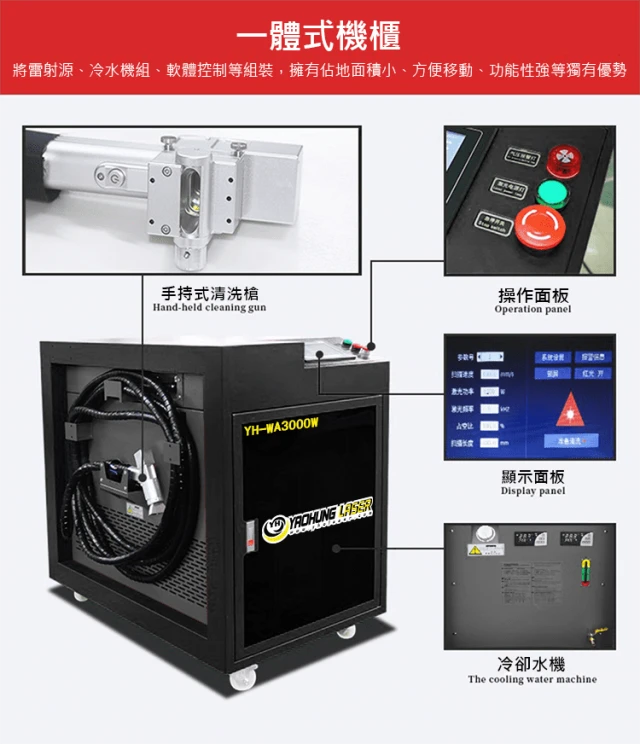

The Handheld Laser Cleaner is designed for large-area rust removal and heavy surface contamination cleaning. Using high-power linear laser scanning, it quickly removes rust, coatings, and weld marks.

With a cleaning distance of up to 800 mm, it is ideal for steel structures, equipment housings, and large plates, making it a practical tool for rapid on-site deployment.

The Handheld Laser Cleaner emphasizes cleaning efficiency and large-area processing capacity, making it especially suitable for high-volume workpieces and long-duration operations.

For high-precision electronic components or heat-sensitive materials, the Cabinet Laser Cleaner is recommended, as it provides more stable output and automation integration.

The Handheld Laser Cleaner is ergonomically designed for long-duration handling, allowing one-hand operation with optional stand support.

It is highly suitable for takt-time operations, equipment maintenance, and heavy industrial sites, reducing operator fatigue while maintaining cleaning precision.

Optimize Your Workflow with Customized Laser Systems

From concept to configuration — We build it your way.

Explore Custom Solutions