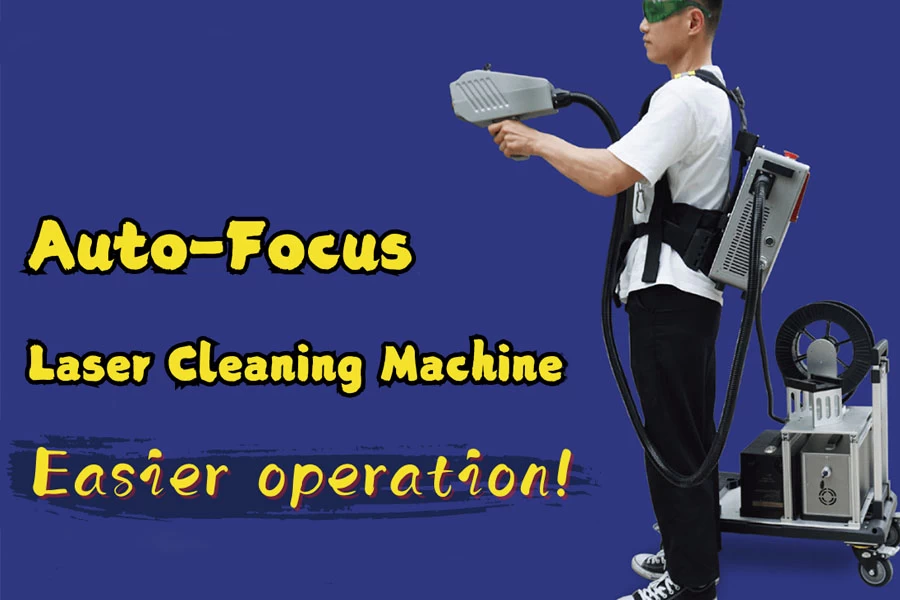

Auto-Focus Laser Cleaning Machine

-

Auto-Focus Laser Cleaning Technology: Effortless Handheld Operation

The effective working distance between the cleaning head and the workpiece has been expanded to 26mm. In contrast, traditional 2D laser cleaning machines have a fixed focal depth of only 2mm, meaning the range has been increased by 13 times. This allows operators to maintain over 90% of cleaning tasks within the effective focal range effortlessly.

-

Beam Control Technology: Higher Cleaning Efficiency

Traditional 2D laser cleaning machines have a fixed beam spot size of around 0.1mm². With 3D auto-focus technology, the beam spot remains at least 0.3mm² during cleaning, covering an area 9 times larger than a conventional 2D cleaning machine in the same duration. For applications such as removing thin paint layers, grease, or dirt, the workpiece undergoes more laser cleaning cycles per unit time, ensuring greater efficiency and a cleaner surface.

-

Defocus Control Technology

When the workpiece is within the focal range, the laser's erosion ability is at its strongest, which may cause surface damage. For sensitive precision workpieces requiring the removal of light rust, oil stains, or thin coatings without damaging the base material, The defocus cleaning mode ensures effective removal while protecting the substrate.

-

Applications

Rapid rust and oxide removal, cleaning of metal surfaces in confined spaces; removal of grease, resin, adhesives, dust, stains, and production residues; pre-welding or pre-bonding, paint stripping, rust removal, degreasing, and post-welding oxide removal; mold cleaning for tire molds, electronic molds, and food molds; oil removal after precision component production; oxidation removal, paint stripping, and rust removal in aerospace, weaponry, and shipbuilding industries; cleaning of cultural artifacts, stone surfaces, and building exteriors.

Update : 2025-08-06