Laser Cleaning in Pre-Treatment|Solving Traditional Cleaning Limitations

Not All Cleaning Is Equal: Laser Cleaning Solves Pre-Treatment Gaps

In today's manufacturing environment, where precision and stability are paramount, many recurring defects—such as welding porosity, coating delamination, or pattern misalignment—aren’t caused by machinery or parameters, but by a commonly overlooked step: pre-treatment cleaning.

It's Not That Cleaning Wasn’t Done — It Just Wasn’t Done Right

Many production lines have cleaning steps in place, but the following issues still frequently occur:

- Conventional methods fail to reach corners, holes, or tight geometries

- Residual oil films remain due to insufficient cleaning force

- Soft or sensitive materials are scratched or slightly deformed

These seemingly small residues can interfere with subsequent processes both physically and chemically:

- Oil on aluminum before welding can cause porosity

- Oxide on mold steel reduces coating adhesion

- Particles on etched surfaces lower pattern precision

These problems not only reduce yield but often result in costly rework and delivery delays.

Limitations of Traditional Cleaning Methods

| Method | Advantages | Limitations |

|---|---|---|

| Chemical Cleaning | Strong degreasing power, suitable for most metals | Requires waste liquid treatment, material limitations, corrosion risk |

| Abrasive Blasting | Removes rust, roughens surfaces | Dusty, hard to treat fine details, may alter dimensions |

| Ultrasonic Cleaning | Good for holes and complex shapes | Limited by tank size, can’t remove heavy contamination |

| Polishing / Grinding | Provides high surface finish | Not suitable for irregular shapes, may cause wear or scratches |

These methods still work for large volumes or simple geometries, but when parts become more complex and cleanliness requirements tighten, an additional technology is needed.

Explore our full laser cleaning solutions and find out how they can add value to your pre-treatment workflow.

Laser Cleaning Isn’t a Cure-All—But It Fills the Gaps

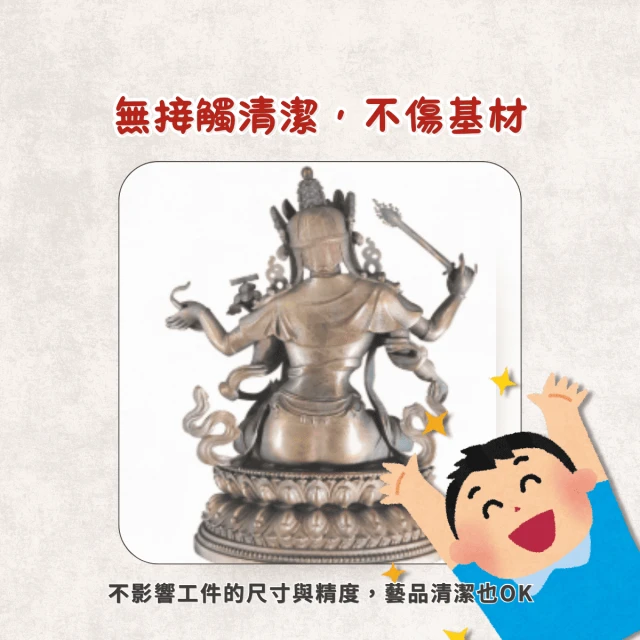

- Non-contact process: No damage to base material or dimensional change—ideal for high-precision manufacturing

- Dry operation: No chemicals, no wastewater, better for safety and sustainability

- High adaptability: Works with various metals, odd shapes, and large parts

- Automation-ready: Can integrate with robotic arms or multi-axis platforms

Common Use Cases and Workpieces

- Oil and oxide removal on aluminum profiles or steel plates before welding

- Mold refurbishment or pre-etching surface prep

- Pre-treatment of weld joints on complex or tubular parts

- Rust and residue removal on rebar or cement-based building components

- Pre-coating prep for stainless steel or copper alloy parts

- Consumable-free, dry cleaning of precision components

When Should You Rethink Your Cleaning Strategy?

- Parts with grooves, holes, and hard-to-reach features

- High-precision applications requiring zero surface damage

- Diverse materials incompatible with a single chemical

- Need to reduce waste and cleaning consumables

- Automation planning with integration potential

In practical terms, laser cleaning removes oxide from steel without chemicals. It supports even large, irregular structures and can be used outdoors. For small parts, it removes burn marks and residue with zero contact—preserving accuracy.

Frequently Asked Questions

No. It's a non-contact method that uses energy to remove surface contaminants without harming the substrate—when parameters are properly set.

Oil, oxide layers, rust, old coatings, and some adhesives—on materials like steel, stainless steel, aluminum, copper, and mold steel.

Yes. Modular equipment supports handheld, platform, or robotic configurations—adaptable to part and shape.

Definitely. Especially when precision, shape complexity, or cost reduction are priorities—laser cleaning is a strong complementary solution.

Even the Best Equipment Can’t Save You From Poor Cleaning

When yield drops or defects repeat, don’t just blame the tools. Surface contamination is often the silent culprit behind downstream failure. Laser cleaning isn't here to replace everything, but it fills the gaps where traditional methods fall short.

We’re happy to assess whether laser cleaning is a good fit for your process— based on materials, part geometry, and on-site conditions. Sample testing and technical advice are available.

View Laser Cleaning Equipment Models & Applications

- Handheld Backpack-Type Laser Cleaners

- Trolley-Type Laser Cleaners

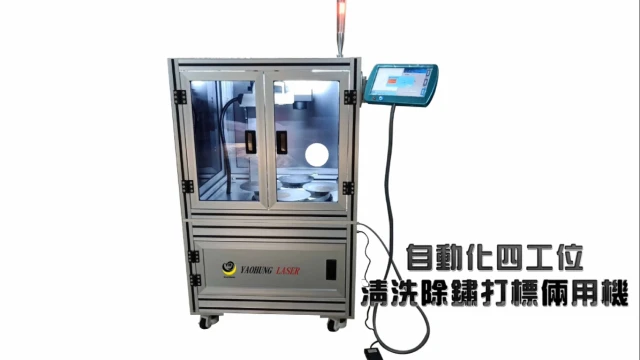

- Cabinet-Type Laser Cleaners

- Handheld-Type Laser Cleaners

Explore our full laser cleaning solutions and find out how they can add value to your pre-treatment workflow.

Update : 2025-10-14