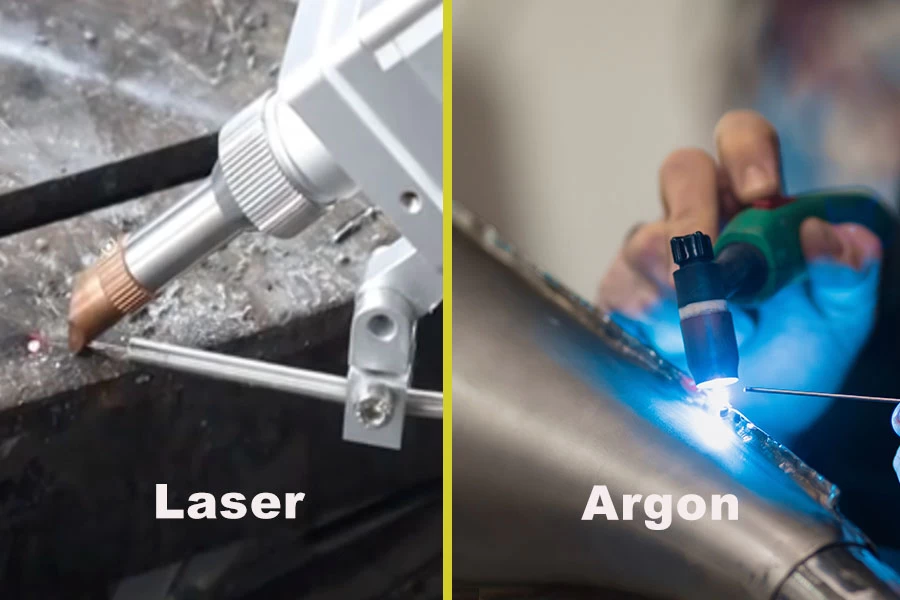

Argon vs. Laser Welding: Which Is Better for Precision Work?A Practical Comparison for Modern Manufacturers

TIG or Laser Welding? Making the Right Choice for Precision Manufacturing

In today’s production environment, welding is more than just a joining method—it plays a critical role in product quality, process reliability, and even customer retention.

As products become lighter, thinner, and more intricate, manufacturers are increasingly faced with a key decision: continue using the well-established TIG process, or upgrade to the faster, more flexible laser welding approach?

This article steps away from theory and dives into practical, real-world insights. We’ll compare both methods in terms of heat control, material compatibility, environmental impact, and operator safety so you can choose the welding solution that truly fits your production needs.

How Do TIG and Laser Welding Compare in Precision Applications?

Heat Input & Deformation Control: Laser Offers Better Precision

Laser welding delivers a highly concentrated heat source and a narrow heat-affected zone (HAZ), minimizing warping risks on thin sheets (0.1–3 mm) and complex parts. TIG, while stable, disperses heat more widely—making it harder to control on ultra-thin or intricate geometries.

Best suited for: precision sheet metal, stainless steel kitchenware, and electronics casings

Material Flexibility & Weld Accuracy: Designed for High Yields

Laser welding’s high energy density enables clean, narrow seams and excellent performance on heat-conductive or reflective materials, such as aluminum, copper, and titanium. With scanning heads or wire feeding, it delivers precise control. TIG still shines in carbon steel and thicker materials—well-suited for general fabrication and structural components.

Ideal for: joining dissimilar materials, multilayer components, and applications requiring a high surface finish

Energy Use & Carbon Footprint: Laser Is the Greener Option

Average exhaust gas emissions per ton of metal processed:

- TIG welding: approx. 20 kg

- Laser welding: approx. 2 kg

Laser machines start and stop quickly, consume less power, and are especially efficient in automated or repetitive welding tasks—making them a strong fit for energy-conscious manufacturers.

Sustainability impact: supports ESG initiatives and ISO 14064 / 14001 certification goals

Operator Safety & Health: Reduced Exposure, Fewer Risks

Laser welding produces little to no smoke or spatter, minimizing respiratory and hearing hazards for operators. Additionally, laser systems integrate easily with automation, reducing human exposure to high heat and intense light during welding.

Workplace benefit: lowers long-term health risks and improves overall ergonomics and safety

Human Factors Do Matter

Technical specs are just one part of the equation. In reality, it’s the day-to-day experience of machine operators, the maintenance challenges, and floor-level frustrations that often determine whether a technology succeeds or fails.

We’ve seen clients go from “I’m worried a new system might slow us down” to “We can’t go back—the old machines just don’t cut it anymore.” Not because laser welding looks impressive on paper, but because it solved real problems—bottlenecks, rework, low yields—and helped streamline their production lines.

This article isn’t about proving which method is better. It’s about helping you ask the right questions. If you’re working on precision parts and constantly battling deformation, rework, environmental issues, or operator fatigue... maybe it’s time to take a new look at your welding strategy.

Conclusion: TIG Is Reliable, But Laser Welding Aligns with Precision and Progress

Each process has its place. The key is knowing when and where to use it:

-

If you’re welding structural steel, large frames, or focused on cost-first procurement, TIG remains a solid, dependable option.

-

But if your production demands high precision, diverse materials, and long-term scalability through automation and ESG goals, laser welding offers a forward-looking solution built for the future.

Need Welding Solutions? Yao Hung Can Help

Phone : +886-4-25665901

Address : No. 11, Aly. 12, Ln. 218, Sec. 4, Minsheng Rd., Daya Dist., Taichung City 428, Taiwan (R.O.C.)

Email : yaohung@yholaser.com

Facebook : https://www.facebook.com/yao.hung168/

Update : 2025-10-14